Mastering CNC Acrylic Cutting: Essential Tips and Techniques

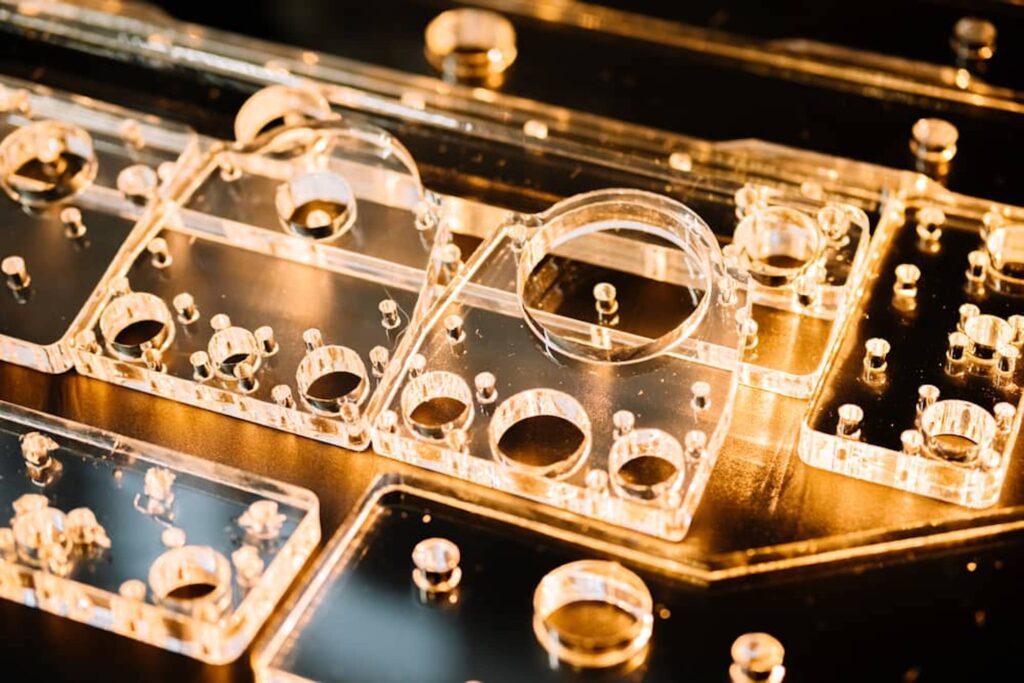

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile material prized for its clarity, durability, and ease of machining. Its applications range from signage and displays to protective screens and intricate art pieces. However, achieving clean, precise cuts with CNC (Computer Numerical Control) machines requires a nuanced understanding of the material properties and the right cutting techniques. This comprehensive guide provides essential CNC acrylic cutting tips to help you optimize your processes, minimize errors, and produce high-quality results.

Understanding Acrylic and Its Properties

Before diving into the specifics of CNC acrylic cutting, it’s crucial to understand the material itself. Acrylic comes in two primary forms: cast acrylic and extruded acrylic. Cast acrylic is manufactured by pouring liquid acrylic between two sheets of glass or metal, where it hardens. This process results in a material with uniform properties, making it ideal for intricate designs and engraving. Extruded acrylic, on the other hand, is produced by pushing molten acrylic through a die. While it’s typically more cost-effective, extruded acrylic can have internal stresses that may cause it to warp or crack during machining. Knowing which type of acrylic you’re working with is the first step in a successful CNC acrylic cutting project.

Essential CNC Acrylic Cutting Tips: Machine Setup

Choosing the Right CNC Machine

While most CNC routers can cut acrylic, selecting a machine with sufficient rigidity and precision is paramount. Look for a machine with a sturdy frame, accurate lead screws, and a spindle capable of maintaining consistent speeds. Consider the bed size and travel distance to accommodate your project dimensions. Investing in a quality CNC machine will significantly improve the accuracy and repeatability of your CNC acrylic cutting.

Optimizing Spindle Speed and Feed Rate

Spindle speed and feed rate are critical parameters in CNC acrylic cutting. Too high a speed can generate excessive heat, leading to melting or chipping. Too low a speed can result in rough edges and inefficient cutting. A good starting point is a spindle speed between 12,000 and 18,000 RPM and a feed rate between 50 and 100 inches per minute. However, these values may need to be adjusted based on the thickness of the acrylic, the type of cutting tool, and the specific CNC machine. Experimentation is often necessary to find the optimal settings for your particular setup.

Securing the Acrylic Sheet

Properly securing the acrylic sheet to the CNC bed is essential to prevent movement and vibration during cutting. Vacuum tables are ideal for larger sheets, providing uniform holding force. For smaller pieces, double-sided tape or clamps can be used, but ensure that the clamping force is evenly distributed to avoid distorting the material. Consider using a sacrificial layer beneath the acrylic to protect the CNC bed and prevent splintering on the underside of the cut.

Choosing the Right Cutting Tools for CNC Acrylic Cutting

Selecting the Appropriate End Mill

The choice of end mill significantly impacts the quality of the cut. Single-flute or two-flute spiral upcut end mills are generally recommended for CNC acrylic cutting. The upcut design helps to evacuate chips, preventing them from re-welding to the acrylic. Look for end mills specifically designed for plastics, as they typically have sharper cutting edges and optimized geometries to minimize heat buildup. Polished flutes can also help to reduce friction and improve chip evacuation. Regularly inspect your end mills for wear and tear, and replace them as needed to maintain cut quality. [See also: End Mill Sharpening Techniques]

End Mill Material and Coating

Carbide end mills are the preferred choice for CNC acrylic cutting due to their hardness and heat resistance. Coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) can further enhance the tool’s performance by reducing friction and increasing wear resistance. However, be cautious when using coated end mills, as some coatings can generate excessive heat, especially at higher cutting speeds. Experiment with different coatings to determine which works best for your specific application.

Maintaining Sharp Cutting Edges

Dull cutting edges are a primary cause of poor cut quality in CNC acrylic cutting. Regularly inspect your end mills for signs of wear, such as chipped edges or rounded corners. Consider investing in a tool grinder or sharpener to maintain the sharpness of your end mills. Alternatively, you can send your end mills to a professional sharpening service. Keeping your cutting tools sharp will not only improve the quality of your cuts but also extend the life of your CNC machine.

Optimizing Cutting Parameters for Clean Cuts

Controlling Heat Buildup

Heat is the enemy of clean CNC acrylic cutting. Excessive heat can cause the acrylic to melt, warp, or chip. To minimize heat buildup, use a combination of appropriate spindle speed, feed rate, and cutting tool. Consider using a coolant or compressed air to dissipate heat and prevent chips from re-welding to the acrylic. Avoid prolonged dwell times in a single area, as this can concentrate heat and lead to melting. Implement a multi-pass cutting strategy, where you remove small amounts of material with each pass, to reduce heat generation. [See also: Coolant Systems for CNC Routers]

Implementing a Multi-Pass Cutting Strategy

A multi-pass cutting strategy involves cutting the acrylic in multiple passes, removing a small amount of material with each pass. This approach reduces heat buildup, minimizes stress on the material, and produces cleaner edges. The depth of each pass should be carefully chosen based on the thickness of the acrylic and the capabilities of the CNC machine. A general guideline is to use a depth of cut that is no more than half the diameter of the cutting tool. Experiment with different depths of cut to find the optimal balance between speed and quality.

Utilizing Climb Milling

Climb milling, also known as down milling, is a cutting technique where the cutting tool moves in the same direction as the feed rate. This technique produces a smoother finish and reduces the risk of chipping, especially on the top edge of the acrylic. However, climb milling can also generate more heat than conventional milling. Therefore, it’s essential to carefully monitor the temperature of the acrylic and adjust the cutting parameters accordingly. In some cases, a combination of climb milling and conventional milling may be the best approach.

Post-Processing Techniques for Acrylic

Deburring and Edge Finishing

Even with the best cutting techniques, some deburring and edge finishing may be necessary to achieve a perfect finish. Use a fine-grit sandpaper or a deburring tool to remove any sharp edges or burrs. For a polished edge, consider flame polishing or vapor polishing. Flame polishing involves briefly exposing the edge to a flame, which melts the surface and creates a smooth, glossy finish. Vapor polishing uses a chemical vapor to dissolve the surface of the acrylic, resulting in a similar effect. Exercise caution when using these techniques, as they can easily damage the acrylic if not done properly. [See also: Acrylic Polishing Methods]

Cleaning and Protecting the Acrylic

After cutting and finishing the acrylic, it’s essential to clean and protect it from scratches and damage. Use a soft, lint-free cloth and a mild soap solution to remove any dust, fingerprints, or residue. Avoid using abrasive cleaners or solvents, as these can damage the surface of the acrylic. Consider applying a protective coating to prevent scratches and UV damage. Store the acrylic in a clean, dry place away from direct sunlight to prevent discoloration.

Troubleshooting Common CNC Acrylic Cutting Problems

Chipping and Cracking

Chipping and cracking are common problems in CNC acrylic cutting. These issues are often caused by excessive heat, improper cutting parameters, or dull cutting tools. To prevent chipping and cracking, ensure that you are using the correct spindle speed, feed rate, and cutting tool. Implement a multi-pass cutting strategy to reduce heat buildup. Regularly inspect your end mills for wear and tear, and replace them as needed. Consider using a coolant or compressed air to dissipate heat. If the problem persists, try reducing the depth of cut or adjusting the feed rate.

Melting and Welding

Melting and welding occur when the acrylic becomes too hot and the chips re-weld to the material. This can result in a rough surface finish and poor dimensional accuracy. To prevent melting and welding, reduce the spindle speed and feed rate. Use a cutting tool with polished flutes to improve chip evacuation. Consider using a coolant or compressed air to dissipate heat. Avoid prolonged dwell times in a single area. If the problem persists, try increasing the feed rate or reducing the depth of cut.

Rough Edges and Poor Surface Finish

Rough edges and a poor surface finish can be caused by a variety of factors, including improper cutting parameters, dull cutting tools, or vibration. To improve the surface finish, ensure that you are using the correct spindle speed, feed rate, and cutting tool. Implement climb milling to produce a smoother finish. Regularly inspect your end mills for wear and tear, and replace them as needed. Ensure that the acrylic sheet is properly secured to the CNC bed to prevent vibration. Consider using a finer grit sandpaper or a polishing compound to smooth the edges.

Conclusion

Mastering CNC acrylic cutting requires a combination of knowledge, skill, and attention to detail. By understanding the properties of acrylic, selecting the right cutting tools, optimizing cutting parameters, and implementing post-processing techniques, you can achieve clean, precise cuts and produce high-quality results. Remember to troubleshoot common problems and continuously refine your processes to improve efficiency and minimize errors. With practice and persistence, you can become a proficient CNC acrylic cutting specialist.